A TRUSTED FIRE TRUCK REPAIR CENTER

At SVI Refurb, we’re committed to keeping more fire trucks on the road. As one of the nation’s most trusted fire truck repair centers, SVI Refurb offers a long list of fire truck repair services at our 160,000-square-foot Colorado facility, including truck inspections, accident repair and maintenance contracts for every make and model of fire apparatus.

SVI Refurb follows NFPA 1911: Standard for the Inspection, Maintenance, Testing and Retirement of In-Service Automotive Apparatus.

FIRE TRUCK ACCIDENT REPAIR

We can tackle the toughest body collision repairs, offering door repair, panel replacement and body fabrication, along with in-house paint and finishing services.

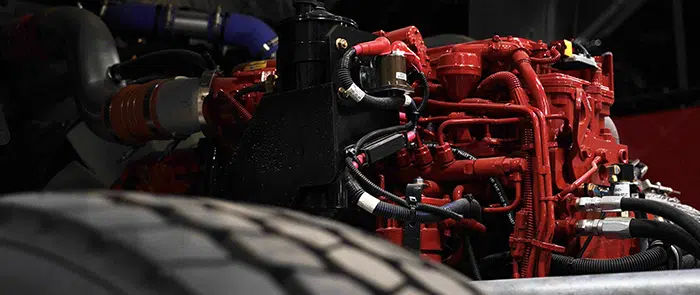

CHASSIS, ENGINE AND DRIVELINE SERVICE

FIRE PUMP REPAIRS AND TANK REPLACEMENT

We can repair faulty pumps, replace cracked tanks and follow it all up with a comprehensive pump inspection. Among our list of pump repair items, we can tackle pump seals, pump gauges (frozen gauges or complete replacement) and valve rebuilds (transfer valves, relief valves, pump valves and drain valves). We also can upgrade valves, hoses, panel lights and LDH manifolds.

ELECTRICAL/HYDRAULIC TROUBLESHOOTING

AERIAL REPAIR

With a 160,000-square-foot facility, SVI Refurb has the room to tackle your aerial services, including preventive maintenance and aerial troubleshooting and repairs, including wear pad adjustments, hydraulic cylinder rebuilds and aerial parts replacement (sheave wheels, hydro-motion swivels and extension/retraction cables).

SVI REFURB’S FIRE TRUCK MAINTENANCE SERVICES

Suggested fire truck maintenance checklist items at the department:

- Complete an Apparatus Inspection Form after each shift (or weekly, if you’re at a volunteer department), as suggested by NFPA 1911 4.5.4.

- Flush your fire pump monthly, or after any operation where water was drafted, supplied by another pump or hooked to a hydrant. This will clear debris that may have entered the pump during use.

- Flush your pumper’s water tank at least twice a year. This routine flush will clear debris that can damage valves, valves or governors.

- Clean and lubricate all latches, hinges, springs and rollers of cab/compartment doors on a monthly basis.

Suggested fire truck maintenance checklist items at your service center:

Perform a comprehensive quarterly/annual inspection, as recommended by NFPA 1911 4.5.5.